Articles

-

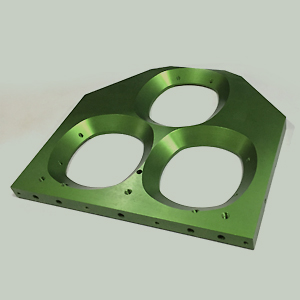

Posted: Jan 25, 2017 Clicks: 1105Anodic oxidation has a wide range of applications in industry. It can be used to prevent products from corrosion, such as abrasion resistant layer, electrical insulation layer, paint bottom layer and bottom layer, etc. Here are some characteristics of anodic oxidation. 1. Prevent corrosion of aluminum product ...

Posted: Jan 25, 2017 Clicks: 1105Anodic oxidation has a wide range of applications in industry. It can be used to prevent products from corrosion, such as abrasion resistant layer, electrical insulation layer, paint bottom layer and bottom layer, etc. Here are some characteristics of anodic oxidation. 1. Prevent corrosion of aluminum product ... -

Posted: Jan 25, 2017 Clicks: 1003Here are some measures for dealing the waste in stamping process: 1. Raw materials have to match with the specified technology.(Strictly check the specifications and grades of raw materials. If possible, those workpieces, which have high quality requirements, should be tested with the precise size and surface quality.)...

Posted: Jan 25, 2017 Clicks: 1003Here are some measures for dealing the waste in stamping process: 1. Raw materials have to match with the specified technology.(Strictly check the specifications and grades of raw materials. If possible, those workpieces, which have high quality requirements, should be tested with the precise size and surface quality.)... -

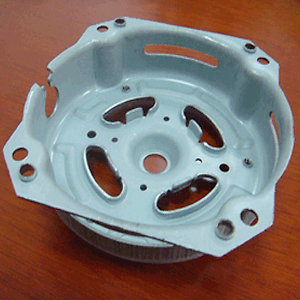

Posted: Aug 06, 2015 Clicks: 1429Compared with casting parts and forging parts, stamping parts have thin thickness, light weight and high hardness. For precise die moulds, the precision can reach micron size. Stamping parts have higher accuracy and consistent dimensions. In general, cold stamping parts do not need machining or just only require few machining....

Posted: Aug 06, 2015 Clicks: 1429Compared with casting parts and forging parts, stamping parts have thin thickness, light weight and high hardness. For precise die moulds, the precision can reach micron size. Stamping parts have higher accuracy and consistent dimensions. In general, cold stamping parts do not need machining or just only require few machining.... -

Posted: Jul 09, 2015 Clicks: 1720The followings are the test methods used for stamping parts. Touching Use clean gauze to clean up the surface of covering parts. Inspector should put on gloves and touch the surface of stamping parts closely, along with lengthways of stamping parts. The method depends on inspectors’ experience. On occasion,...

Posted: Jul 09, 2015 Clicks: 1720The followings are the test methods used for stamping parts. Touching Use clean gauze to clean up the surface of covering parts. Inspector should put on gloves and touch the surface of stamping parts closely, along with lengthways of stamping parts. The method depends on inspectors’ experience. On occasion,... -

Posted: Jul 01, 2015 Clicks: 1652Rockwell hardness tester is mainly used for hardness measurement on stamping parts. For small stamping parts having a complex shape, the surface is too small to be tested. So, small stamping parts cannot be measured by using common desk Rockwell hardness tester. Stamping parts processing mainly includes blanking,...

Posted: Jul 01, 2015 Clicks: 1652Rockwell hardness tester is mainly used for hardness measurement on stamping parts. For small stamping parts having a complex shape, the surface is too small to be tested. So, small stamping parts cannot be measured by using common desk Rockwell hardness tester. Stamping parts processing mainly includes blanking,... -

Posted: Jun 19, 2015 Clicks: 1534The production of stamping parts is a shaping process of plates, strips, pipes and profiles imposed by external forces from press machines and moulds to give rise to plastic deformation or separation so as to achieve stamping parts with required shape and dimension. As with forging, stamping is also plastic processing...

Posted: Jun 19, 2015 Clicks: 1534The production of stamping parts is a shaping process of plates, strips, pipes and profiles imposed by external forces from press machines and moulds to give rise to plastic deformation or separation so as to achieve stamping parts with required shape and dimension. As with forging, stamping is also plastic processing... -

Posted: May 27, 2015 Clicks: 1609Door hinge is a device that allows the flexible turning or pivoting of a door for opening or closing. Because door hinges are often used, choosing good quality door hinges is very important. How to choose such quality door hinges is described below: 1. Checking surface. Check if surfaces of door hinges are smooth...

Posted: May 27, 2015 Clicks: 1609Door hinge is a device that allows the flexible turning or pivoting of a door for opening or closing. Because door hinges are often used, choosing good quality door hinges is very important. How to choose such quality door hinges is described below: 1. Checking surface. Check if surfaces of door hinges are smooth... -

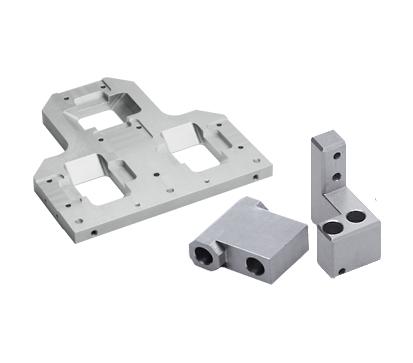

Posted: May 11, 2015 Clicks: 2123The industries utilizing micro system technology are among the world’s fastest-growing industries. Such industries manufacture tiny but high-precision parts which are widely applied in biomedical equipment, optical and micro-electronics (like mobile communication and computer components) industries and so on. The...

Posted: May 11, 2015 Clicks: 2123The industries utilizing micro system technology are among the world’s fastest-growing industries. Such industries manufacture tiny but high-precision parts which are widely applied in biomedical equipment, optical and micro-electronics (like mobile communication and computer components) industries and so on. The... -

Posted: May 06, 2015 Clicks: 14191. Introduction of stainless steel categories Main components of stainless steels are composed of various high quality metallic elements like Cr, Ni, Mo, Ti, etc. Commonly used stainless steels include chromium stainless steels (Cr≥12%) and Ni-Cr stainless steels (Cr≥18%; Ni≥12%). In terms of metallurgical structure,...

Posted: May 06, 2015 Clicks: 14191. Introduction of stainless steel categories Main components of stainless steels are composed of various high quality metallic elements like Cr, Ni, Mo, Ti, etc. Commonly used stainless steels include chromium stainless steels (Cr≥12%) and Ni-Cr stainless steels (Cr≥18%; Ni≥12%). In terms of metallurgical structure,...