Ducoo provides different kinds of metal surface treatment technology and process according to customer’s technical requirement. We have met the requirement of different areas and environment. Our company provides metal surface treatment technology including aluminum normal anodizing, electroplating, electrophoresis, electrochemical polishing, tempering, painting, sandblasting, phosphating, blackening etc.

Let us become a satisfied partner for customers and provide the most satisfactory products!

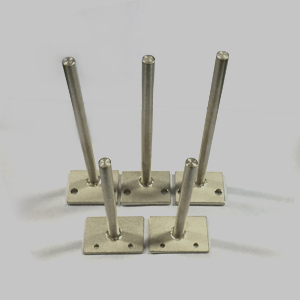

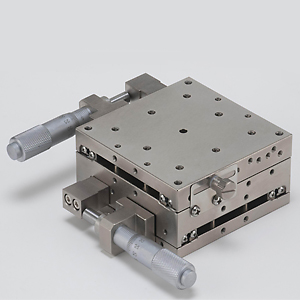

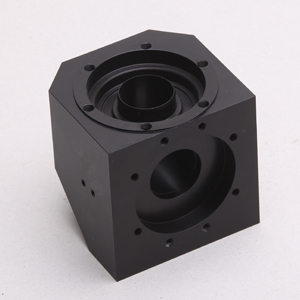

Ducoo Machinery (Xiamen) Co.,Ltd. provides customers with precision machining spare parts, products elements, composite processing and supporting services of aided design and development. Ducoo established a strict quality control system and passed ISO quality system certification. With excellent quality, high efficient international management team, assembly technique and processing technique, Ducoo can guarantee machining precision of products and consistency of quality. The products are wildly used in medical, electronic, non-standard automation equipment, automotive, communications equipment and other fields. The supporting services are provided for a number of well-known international enterprises. Our products are exported to Europe, America, Southeast Asia and other regions.

Our company has its own product assembly line and more than 100 sets of CNC lathe, machining center, lathe, milling machine, surface grinding machine, wire cutting, welding, instrument car, punching machine, compound machine, trenching machine, polishing machine and other specialized processing equipments ,which formed organic combination and reasonable division of labor of the management, technology and cost.

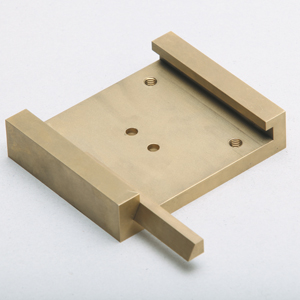

China leading Precision Machining Part OEM Contract Manufacturer Ducoo provides high precision CNC Machining Services in Stainless Steel, Aluminium, Brass.

We have unique perspective about the selection of raw materials, various kinds of processing and metal surface treatment skills. Our professional machining team has been built for the welding parts, sheet-metal parts and stamping parts. We are experienced in many kinds of welding such as laser welding, argon arc welding etc. Sheet metal parts are machined as per customer’s drawing, sample, design and conception.

Sheet Metal Capacity:

1.Laser Cutting machine;

2.CNC punches;

3.Press brakes;

4.Stamping machines;

5.Welding machines;

And more..

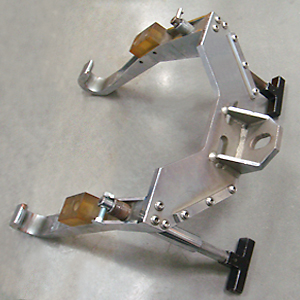

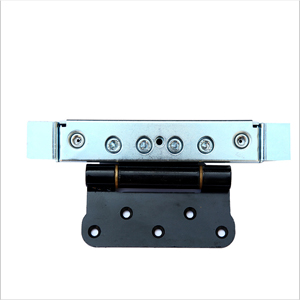

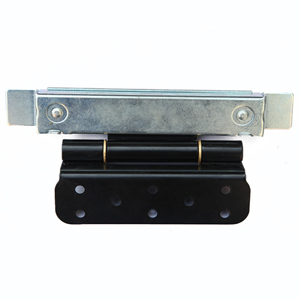

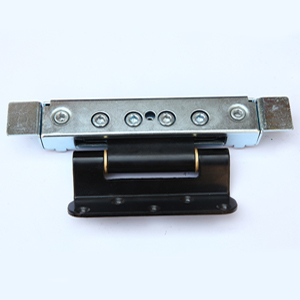

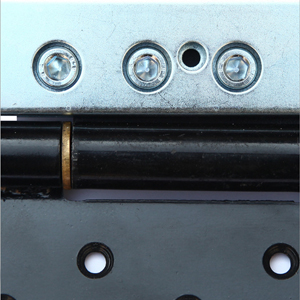

Technical parameters:

1. Corner-55.

2. Material: Iron.

3. Surface treatment: Electrophoresis.

4. Application: Seiko production, used for cast aluminum steel wooden door, high quality security door, three-dimensional adjustable.

Keyword: Hinge, Door hinge, Gravity hinge, 3D Gravity hinge.

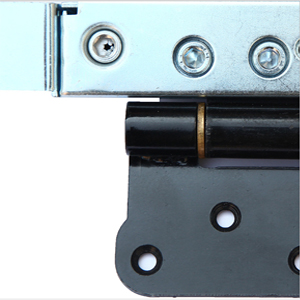

Notes:

1. Select correct hinge that match to material and the required weight class according to configuration or other relevant technical data provided by our company.

2. The two main stress sash interface of hinge and box door profiles needs contact closely, which shall not be suspended and interfered.

3. Most of the hinges are not adjustable hinge, so the machining for door and window profile must be strictly according to the selected hinge profile with suit size to cut.

4. The selected hinge is different according to the characteristics of profile cross section structure, so is the hinge channel. The sealing rubber strip must be selected correctly according to the profile channel left by the allocation of hinge and profile.

5. Sealing strip parts of fan profile interfered in the hinges must be left blank.

6. The concrete bearing capacity is related with the installation and profile of hinge.

I. Summarize

A pneumatic power manipulator is also called pneumatic balance crane, which is a kind of novel aid of labor-saving equipment used for material handling, especially applicable to certain accurate positioning and assembly requirements.

For all industries, the delivering of heavy products, the health, safety of the operators on the scene, the rationality of the operation, the saving of labor, the improvement of production efficiency, the guarantee of product quality and other aspects will have great improvement.

II. Application Areas

They are widely used in mechanical processing and manufacturing, automobile parts, engineering machinery, high-speed train, power distribution, new energy, petroleum, chemical industry, paint, ceramics, textile, communication, building materials, home appliances, electronics, nuclear industry, scientific research, military industry and other fields.

III. Working Principle

It uses principle of force balance skillfully, making the parts form a state of zero gravity. Then the gravity of parts is balanced by a corresponding gas control system, making the operator need a little of operating force in the handling products.

Due to the heavy things are in the floating state while lifting or lowering, the operator can push and pull heavy things with his hands to put the them correctly to any location in space without skilled inching button operation.

IV. Features of the Equipment

1. Precision, Intuition, Handle Easily, High Efficiency, whole floating when balanced, high rigidity without cutting balance.

2. Expired and low pressure protection, not loosen load fixture. It ensures that the products and rate won’t fall and guarantees absolute safety.

3. Strong compatibility. It adjusts regulating valve according the weight of products to realize more cover balance even more balance automatically.

4. Scalability. It realizes more cover balance even more balance automatically according to the need to increase the pneumatic components.

5. High-flexible adhesion clamp can protect the surface of products from scratching.

6. Balance range from 20 kg to 200 kg of many models, meeting the needs of vast majority of users.

7. Fixture and chuck a variety of base can be designed specially according to your requirement: Stationary base, the mobile base, etc. Choose, design and develop depend on the field and environment of products, having reached the best effect of use.

V. Main Parameters of Equipments:

|

Equipment model |

Working pressure (Mpa) |

Maximum radius of operation(m) (design as per the requirement of use) |

Maximum lifting capacity (kg) |

Biggest lifting distance (m)

(design as per the requirement of use) |

|

DCPH50 |

0.6 |

2.5 |

50 |

2 |

|

DCPH75 |

0.6 |

2.5 |

75 |

2 |

|

DCPH100 |

0.6 |

2.5 |

100 |

2 |

|

DCPH125 |

0.6 |

2.5 |

125 |

2 |

|

DCPH150 |

0.6 |

2.5 |

150 |

2 |

|

DCPH200 |

0.6 |

2.5 |

200 |

1.5 |