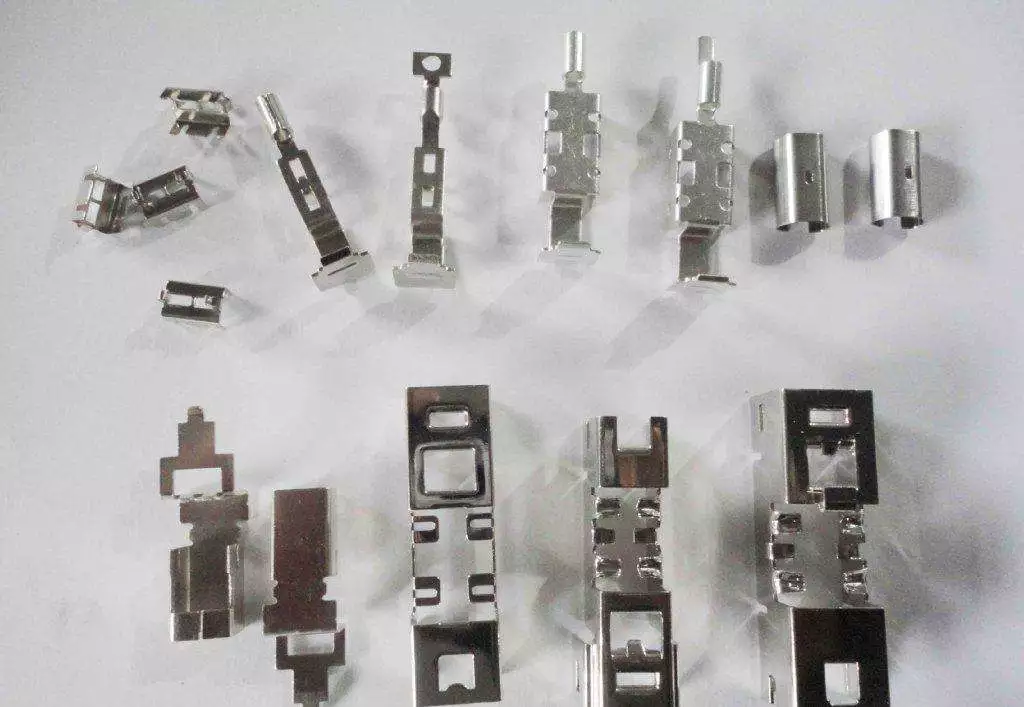

Reasons for Scratches on Stamping Metal Parts

Posted: Jun 02, 2017 Hits: 1842

Stamping(also known as pressing) is the process of forming metal or nonmetal sheets into different shapes through stamping dies with the pressure of the presses.

The market of the stamping metal part is not very perfect and complete. But the market of small-size stamping parts in some areas of southern China is very mature. From the current situation, China's stamping metal part market has the following problems:

1. There are scratches on metal stamping parts. The main cause of scratches on the parts is that there are sharp scratches on the molds or that metal filings fall into the molds. Preventive measures are to polish the scratches on the molds and to remove metal filings in the molds.

2. There are cracks at bottoms of the parts. The main reason is that the plasticity of materials is bad or that blank holders of the molds are too tight. The preventive measures are to replace materials with better plasticity or to relax blank holders.

3. There are wrinkles on the side walls of the stamping parts. The main cause of the wrinkles is that the materials do not have enough thicknesses(thinner than the minimum allowable thicknesses)or that the upper and lower molds are not in the same position when we installed them, resulting in a large gap on one side and a small gap on the other side. We can replace the materials and readjust molds to prevent the problem.

4. The stamping parts lack heights. The reasons and prevention measures for this are as follows:

(1). There are not enough raw materials for metal stamping parts. We should add more raw materials.

(2). There are too big gaps between the molds. We should repair molds when this happens.

(3). Plasticity of the stamping metal parts’ materials is not good. We should have an annealing treatment or replace the original materials with materials of better plasticity.